News

In the dynamic landscape of modern poultry farming, the pursuit of enhanced productivity, superior bird health, and sustainable operations has led to the rise of innovative equipment. Among these, nipple drinkers have emerged as a transformative solution, outshining traditional water troughs in every critical aspect. This comprehensive guide explores the compelling reasons to adopt nipple drinkers, walks you through a detailed installation process, and shares expert maintenance strategies to maximize the value of this investment for your poultry farm.

Why Nipple Drinkers Are a Game-Changer for Poultry Farms

Nipple drinkers are not just a replacement for traditional water systems; they are a strategic upgrade that addresses key challenges faced by poultry farmers. Here’s a breakdown of their unmatched advantages:

Superior Biosecurity & Reduced Costs

Traditional open water troughs are breeding grounds for contamination, as feces, feed residues, and debris easily mix with water, leading to the spread of intestinal diseases and increased bird mortality. Nipple drinkers eliminate this risk by delivering water in a closed system, ensuring clean and safe hydration for flocks. Research shows that farms using nipple drinkers experience a 30-40% reduction in medication expenses due to fewer disease outbreaks, making this equipment a cost-effective long-term investment.

Exceptional Water Conservation

Water waste is a major concern with traditional watering methods, but nipple drinkers tackle this issue head-on. By providing water on-demand, they cut down water waste by up to 80% compared to troughs. This not only lowers utility costs but also keeps the litter dry. Dry litter is crucial for preventing footpad dermatitis in broilers and reducing ammonia emissions, creating a healthier living environment that supports overall bird well-being.

Boosted Growth & Productivity

Consistent access to clean water is vital for maintaining the optimal 2L water : 1kg feed ratio, which directly impacts feed conversion ratios (FCR) and weight gain. Nipple drinkers ensure that every bird has uninterrupted access to water, promoting efficient feed utilization and faster growth. High-flow models are specifically designed to cater to heavy-weight broilers weighing 4kg or more, meeting the demands of modern markets. Additionally, their durable construction minimizes maintenance efforts, making them suitable for farms of all sizes.

Comprehensive Installation Steps for Nipple Drinkers

To fully leverage the benefits of nipple drinkers, proper installation is non-negotiable. Follow these step-by-step instructions for a seamless setup:

1. Pre-Installation Prep

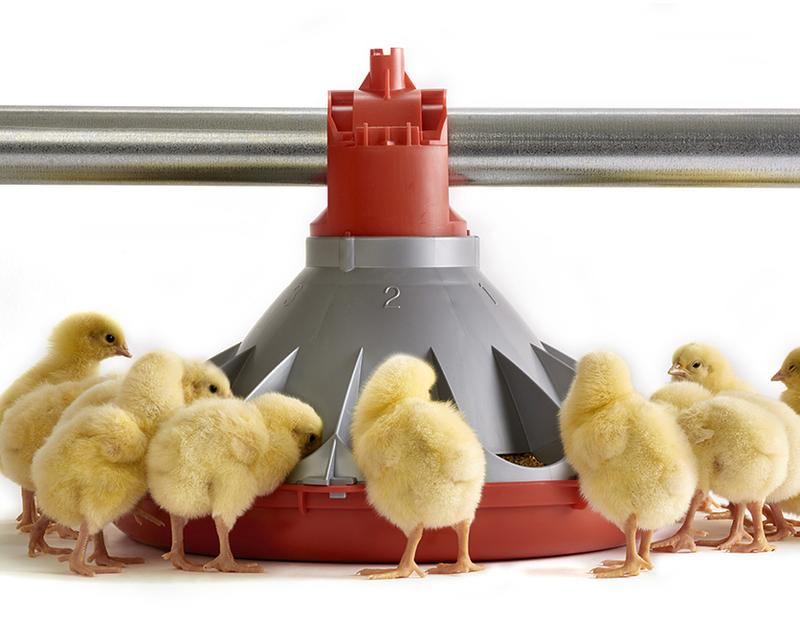

l Choose the Right Drinkers: Select nipple drinkers based on your poultry type and farm scale. For broilers, adjustable-flow options are ideal – Plasson recommends 10-12 broilers per orange/yellow nipple and 12-14 per grey nipple (equipped with a tray).

l Secure Clean Water Source: Install a 50-micron filter on the main water line to prevent clogs in the nipple drinkers. Flush the entire pipeline thoroughly one day before installation to remove sediment and residual chemicals that could damage the equipment.

2. Pipe Sizing & Layout Planning

l Use PVC pipes for the main line (1.5-inch diameter) to serve up to 1,000 birds, and 1-inch diameter pipes for branch lines.

l Design the layout to ensure uniform water pressure: Run the main line along the length of the poultry house, with branch lines positioned perpendicular to it. All lines should have a 1-2 mm/m slope to facilitate flushing and avoid water stagnation.

3. Mounting the Drinker Lines

l Suspend branch lines using aluminum profiles at heights suitable for your birds. For day-old chicks, place the nipple drinkers 5-7 cm above their backs, adjusting gradually as they grow. For adult poultry, position the drinkers at shoulder height to encourage natural drinking behavior.

l Ensure even spacing: 15-20 cm apart for broilers and 25-30 cm for layers. Keep the lines level to guarantee consistent water flow across all nipple drinkers.

4. Precision Pressure Regulation

Install a pressure regulator at the start of the main line to control water flow effectively:

l Day-old chicks: 0.1-0.2 bar (50-60 ml/min flow rate)

l Adult broilers: 0.2-0.3 bar (80-90 ml/min flow rate)

Avoid pressure exceeding 0.5 bar (which causes spillage and wet litter) or falling below optimal levels (leading to inadequate hydration and stunted growth). If your nipple drinkerssupport it, use metering pins to fine-tune flow rates for perfect performance.

5. Post-Installation Testing & Adjustment

l Test each nipple drinkerby pressing the trigger – water should flow steadily without dripping.

l Flush the lines for 1-2 minutes to eliminate air bubbles and remaining debris.

l Monitor your flock’s drinking behavior for 24 hours. If birds struggle to access water, adjust the line height or pressure promptly.

6. Expert Maintenance Tips for Long-Lasting Performance

l Regular Flushing: In summer, flush the lines twice daily (1 minute per 100 feet) to keep water cool and prevent biofilm formation.

l Filter & Nipple Care: Clean filters weekly and inspect nipple drinkers monthly for clogs or leaks. Replace damaged parts immediately to avoid compromising the system.

l Hot Climate Adaptation: In regions with high temperatures, upgrade to high-flow nipple drinkers. These are engineered to meet increased water demand and keep birds comfortable even in extreme conditions.

Adopting nipple drinkers is more than an equipment upgrade – it’s a commitment to the sustainability and profitability of your poultry farm. By combining water efficiency, enhanced biosecurity, and improved flock productivity, these devices create a cleaner, more efficient operation. Whether you raise broilers, layers, or heavy-weight poultry, following the installation and maintenance guidelines in this guide will help you nurture healthier, heavier birds while reducing operational costs. Invest in nipple drinkers today and take your poultry farming to new heights of success.

View More information about chicken farm

View our Youtube More breeding equipment video

Phoenix Breeding Equipment: 20+ years of breeding equipment production and export experience. As a result of our high-quality products and outstanding customer service, we have gained a global sales network reaching Europe, North America, Southeast Asia, Africa, South America, etc. Successfully in use on both family-owned farms and large farm complexes. Providing individual and automatic equipment to feed your livestock: chicken drinking line, chicken feeding line, poultry drinker and feeder, exhaust/ventilation fans, egg Incubator, and so on breeding equipment.

CONTACT US

Phone:+86 19061974162

Email: sales@goldphoenixa.com

Pulished on Jan. 26, 2026

Pulished on Jan. 21, 2026