News

Understanding Poultry Drinking Nipple Fundamentals

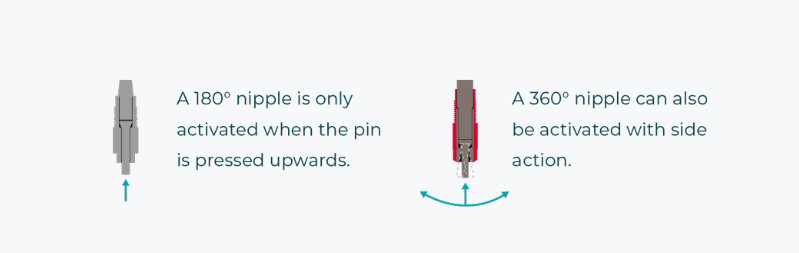

Drinking nipples for poultry operations come in two primary activation types, each designed for specific flock requirements and management systems:

1. Operate through vertical upward pressure on the pin mechanism

2. Allow birds to drink only from the underside of the nipple

3. Ideal for controlled water delivery in mature flocks

1. Feature multi-directional activation (up, down, and sideways)

2. Enable birds to drink from any angle of approach

3. Perfect for young or inexperienced flocks

Optimal Nipple Selection by Poultry Category

Broiler Production Systems

Water constitutes approximately 70% of broiler body composition

Rapid growth demands immediate water access post-placement

Recommended Solution: 360-degree nipples with:

Low activation resistance (20-40g trigger pressure)

Medium flow rate (50-70 mL/min)

Drip cups for starter houses

Pullet Development Programs

Young birds require intuitive drinking systems during critical development

Pecking behavior necessitates easy-to-learn mechanisms

Recommended Solution: 360-degree training nipples featuring:

Bright-colored activation pins

Reduced trigger pressure

Audible water release for behavior reinforcement

Commercial Layer Operations

Commercial Layer Operations

Modern layer systems benefit from consistent drinking technology

Transition from rearing to production facilities is crucial

Recommended Solution: Gradual transition from 360-degree to:

180-degree production nipples

Flow rates of 60-80 mL/min

Optional drip cups based on house environment

Beak-Intact Layer Management

Natural beak morphology requires specialized drinking solutions

Traditional nipples cause excessive water waste

Recommended Solution: 360-degree side-activated nipples with:

Low-flow design (40-50 mL/min)

Extended activation pins

Integrated splash guards

Breeder Stock Management

Controlled water intake is critical for reproductive performance

Overconsumption leads to litter quality issues

Recommended Solution: 180-degree breeder nipples featuring:

Precision flow control (30-50 mL/min)

Delayed shut-off mechanism

Heavy-duty stainless steel construction

Technical Selection Criteria

Material Engineering Considerations

Premium Option: 316L surgical-grade stainless steel

50,000+ activation lifespan

Corrosion-resistant in all water conditions

Economy Option: High-impact polymer composites

10,000-15,000 activation cycles

UV-stabilized for open-house use

Flow Dynamics Optimization

Standard flow parameters:

Pullets: 40-60 mL/min

Layers: 60-80 mL/min

Broilers: 50-70 mL/min

High-temperature adjustments:

Increase flow by 15-20% during heat stress

Implement additional cooling systems

Water Conservation Systems

Essential drip cup configurations:

Broiler starter cups (50mm depth)

Layer production cups (75mm depth)

Anti-perch designs for mature flocks

Water recovery efficiency:

Standard systems: 85-90% efficiency

Conservation systems: 93-95% efficiency

Emerging Technological Advancements

Smart nipple systems featuring:

RFID monitoring of individual bird consumption

Automated flow adjustment based on ambient conditions

Self-diagnosing maintenance alerts

Hygiene innovations:

Antimicrobial surface treatments

In-line UV sterilization compatibility

Quick-disconnect cleaning ports

Global Implementation Standards

European Union Compliance

Mandatory animal welfare provisions:

Beak-intact system requirements

Minimum water access points

Flow verification standards

North American Best Practices

Large-scale integration focuses on:

System durability

Winterization capabilities

Biosecurity protocols

Asian Market Adaptations

Tropical climate modifications:

Enhanced flow rates

Mold-resistant materials

Monsoon-proof housing integration

System Implementation Strategy

Flock Assessment

Age analysis

Beak status evaluation

Production goals

Environmental Review

Housing type examination

Climate pattern evaluation

Water quality testing

Technical Specification

Nipple type determination

Flow rate calculation

Access point density planning

Installation Protocol

Height adjustment guidelines

Line pressure calibration

System flushing procedures

Maintenance Optimization

Daily inspection checklist:

Activation testing

Flow verification

Leak detection

Weekly maintenance:

Deep cleaning protocols

Wear component inspection

Pressure regulation checks

Annual overhaul:

Complete system flush

Component replacement

Performance benchmarking

Performance Metrics Analysis

Key performance indicators:

Water conversion ratios

Flock uniformity metrics

System efficiency ratings

Continuous improvement:

Data tracking systems

Benchmark comparisons

Technology upgrades

Conclusion

Selecting the optimal drinking nipple system requires comprehensive analysis of flock requirements, production objectives, and operational parameters. Modern poultry operations must balance animal welfare considerations with production efficiency through scientifically validated drinking solutions. Implementing the appropriate nipple technology, combined with rigorous maintenance protocols, ensures optimal water utilization, flock health, and operational profitability throughout the production cycle.

Progressive operations should consider phased technology adoption, beginning with core reliability features and advancing toward smart system integration as operational scale and technical capacity permit. Regular system evaluation against industry benchmarks maintains competitive performance in evolving market conditions.

View More information about chicken farm

View our Youtube More breeding equipment video

Phoenix Breeding Equipment: 20+ years of breeding equipment production and export experience. As a result of our high-quality products and outstanding customer service, we have gained a global sales network reaching Europe, North America, Southeast Asia, Africa, South America, etc. Successfully in use on both family-owned farms and large farm complexes. Providing individual and automatic equipment to feed your livestock: chicken drinking line, chicken feeding line, poultry drinker and feeder, exhaust/ventilation fans, egg Incubator, and so on breeding equipment.

CONTACT US

Phone:+86 19061974162

Email: sales@goldphoenixa.com

Pulished on Feb. 06, 2026

Pulished on Jan. 28, 2026